Hi Everyone

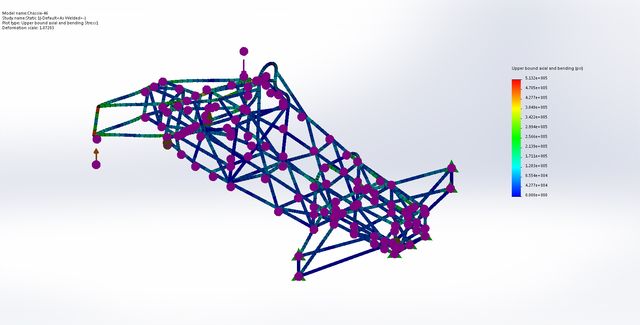

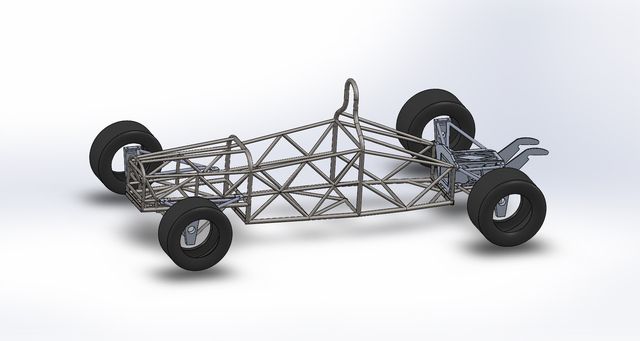

And "Thanks for all the information". Been lurking here for months reading every thing many of you have been kind enough to share. Looking for help and opinions on a build prior to my starting to cut and weld tube for an F1000.

Pretty much too old to seriously consider myself any thing like a serious driver. Although I have been around SCCA, NHRA, and D1 racing for years fabing up cages and machining parts for what seems like decades. All the while never owning a car myself.

This one I intend to be for me.

Reply With Quote

Reply With Quote