Originally Posted by

Matt Conrad

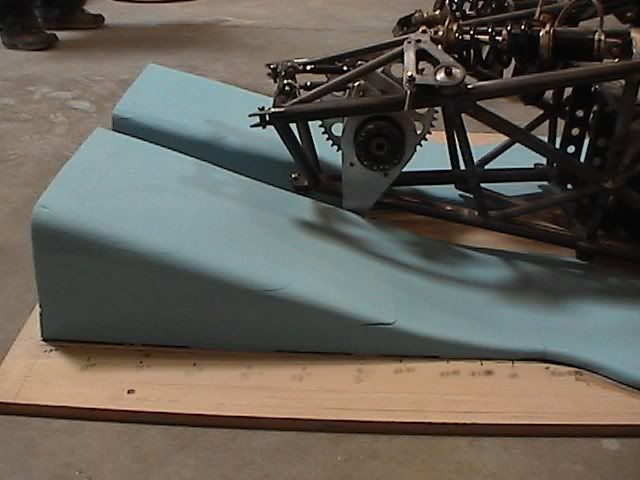

As I stated last weekend, the plan to use a large format 5-axis CNC machine for the body plug didn't work out. Our back-up plan was to do it the old fashioned way and start cutting profiles out of wood and filling the gaps with foam until we had the shape of the car.....but our engineer had a pretty good idea for a different plan of attack.....

Using the computer, he took 155 (or so) "slices" of the car (see below) which we could then have waterjet cut out of 1" foam. Each part has the number cut into it as well as pilot holes for PVC pipe to be used to perfectly align all the parts when they are assembled.

Yes, we'll still have some sanding to do, but I'm confident we've shaved several weeks off the build time doing it this way. The cost? About 10% of what the 5-axis CNC process was going to be, and probably not a whole bunch more than if we were to have used the plywood and 2-part foam.

The parts are being cut today and we should be able to post some photos of the nose section by the weekend.

Matt Conrad

Phoenix Race Cars, Inc.

Reply With Quote

Reply With Quote