Against the advice of almost everyone I not only got a Vee, but also the one said not to get(see this thread). That being said it was purchased for $1000 which included a fairly nice open trailer, spare engine/trans, spare hoop forward bodywork, good cell, fire system, and what I am told is a regional motor.

The car was purchased full well knowing that I would not fit as is. In fact it was purchased without knowing what I would even do with it, or if I would really even bother with racing a Vee...

Well after consulting a few experts, I was divided on what to do. Sell the chassis, find a wider chassis and swap the parts, or make it work. On one hand I was told the vintage chassis was worth something, and on the other hand, it has no logbook and no visible stamp on the roll bar.

My decision hinged on my goals. My goal is to get out on the track, even if it's just with MCSCC. Yes I know there are cheaper ways of getting on the track. So a new roll hoop, and upper frame section is now on order with the bender. Wider and updated as per the rules.

I want to thank everyone for there advice and kind words. I don't expect cheering from you guys after I effectively ignored all your advice, but I figured I owed you at least a play by play. If it turns out to be the predicted nightmare, it will be documented here, and I fully expect criticism.

To rest some fears, I am being aided in this by some seasoned veterans, and although they may not be V guys anymore, they have spent more hours building cars than I have spent alive. They also know more intimately where I am coming from.

So on to day 1(technically day 2 if you include a night of planning, measuring, planning, and measuring)

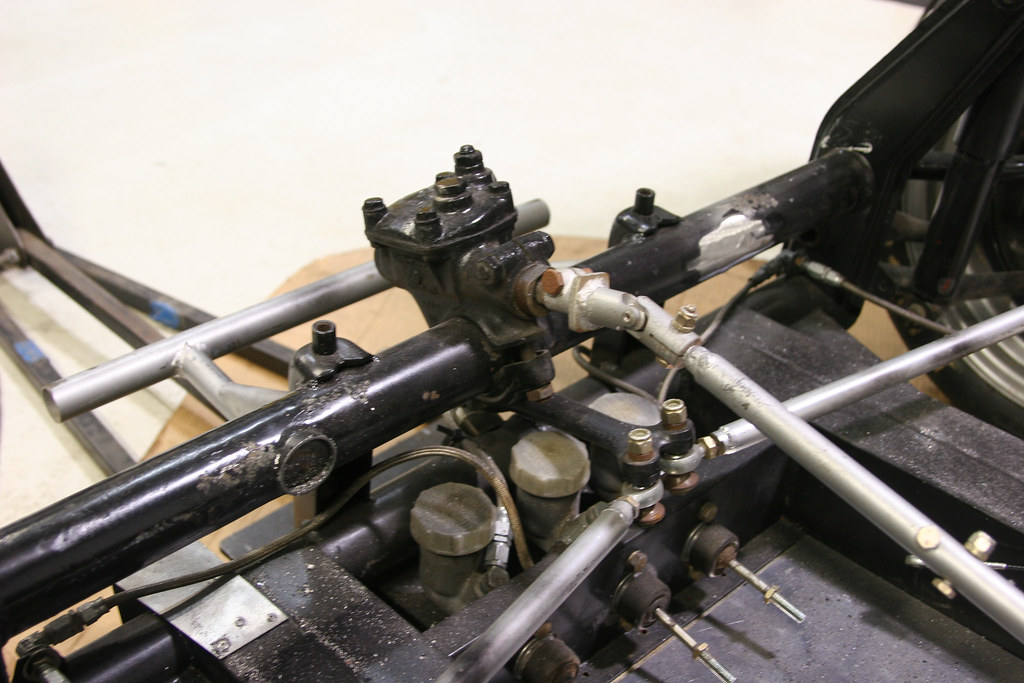

I removed the cell, brakes, firewall, wiring, pedals(need to be changed), and cut the upper frame off. I then cleaned everything smooth. The wider base of the bar might require that I extend the main roll hoop plates, but I hesitated to go that far until I had the bent tube in front of me.

Here are some pictures...

Reply With Quote

Reply With Quote

.

.